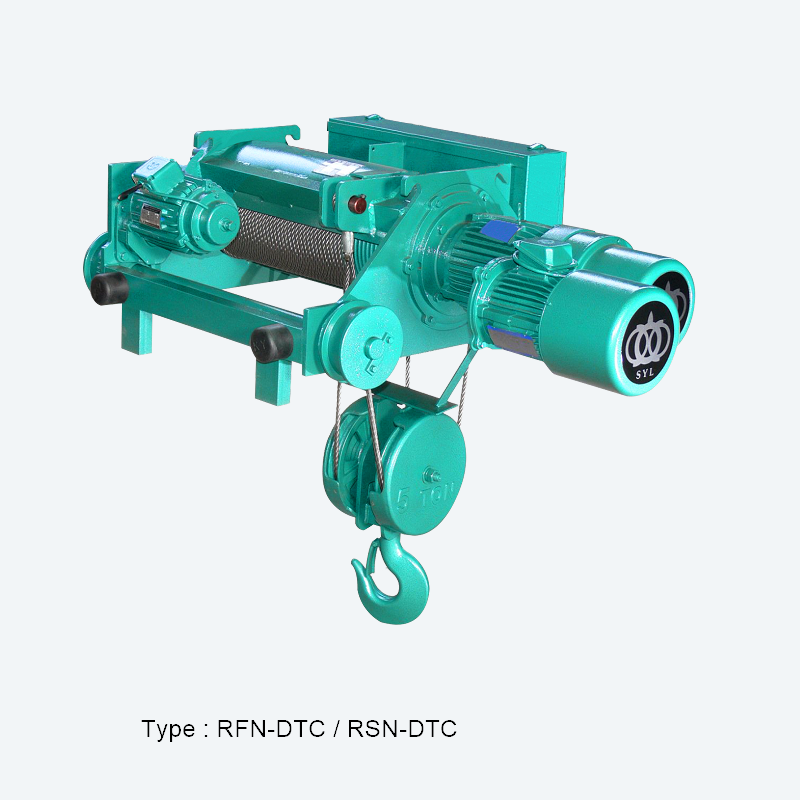

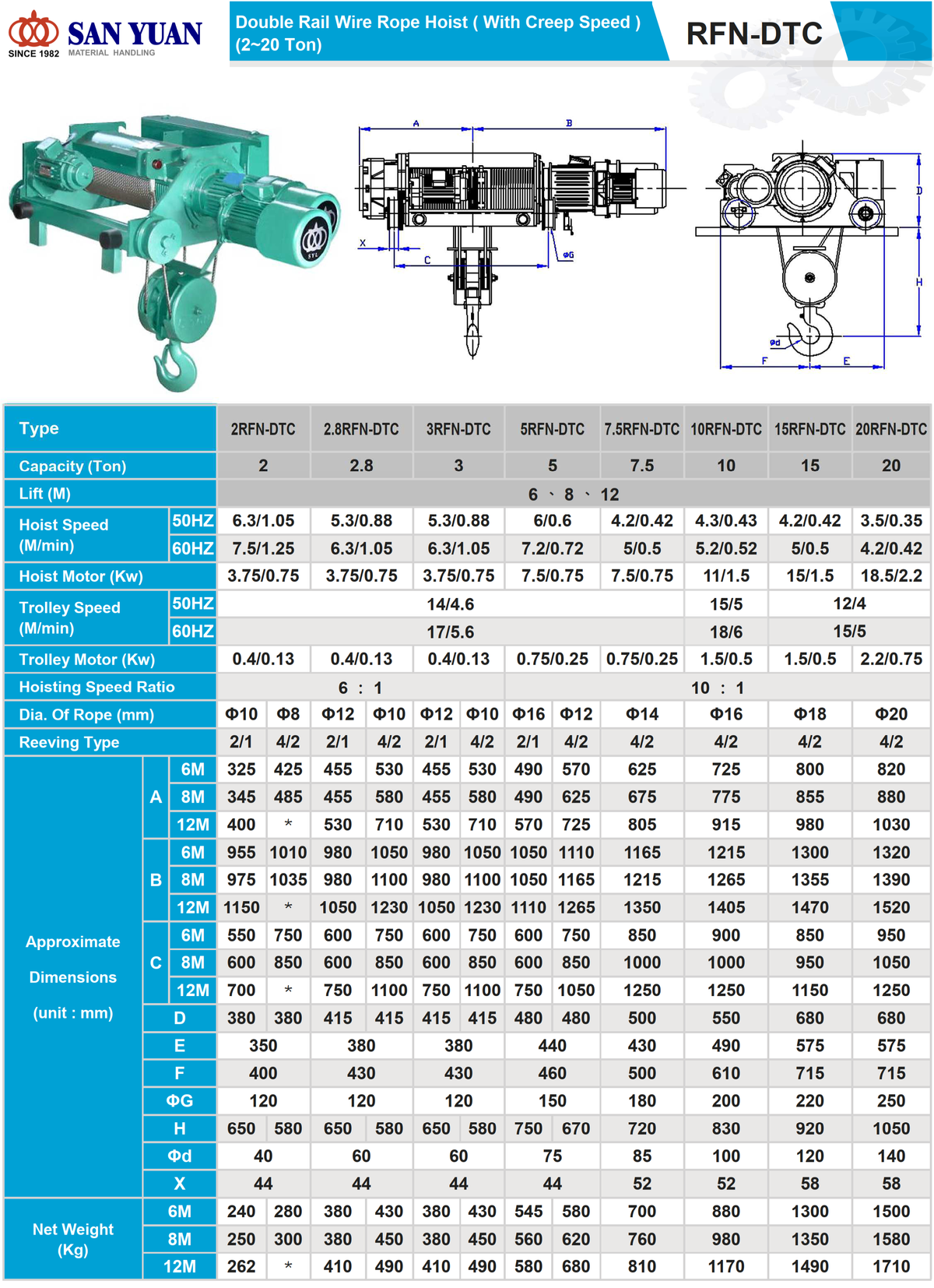

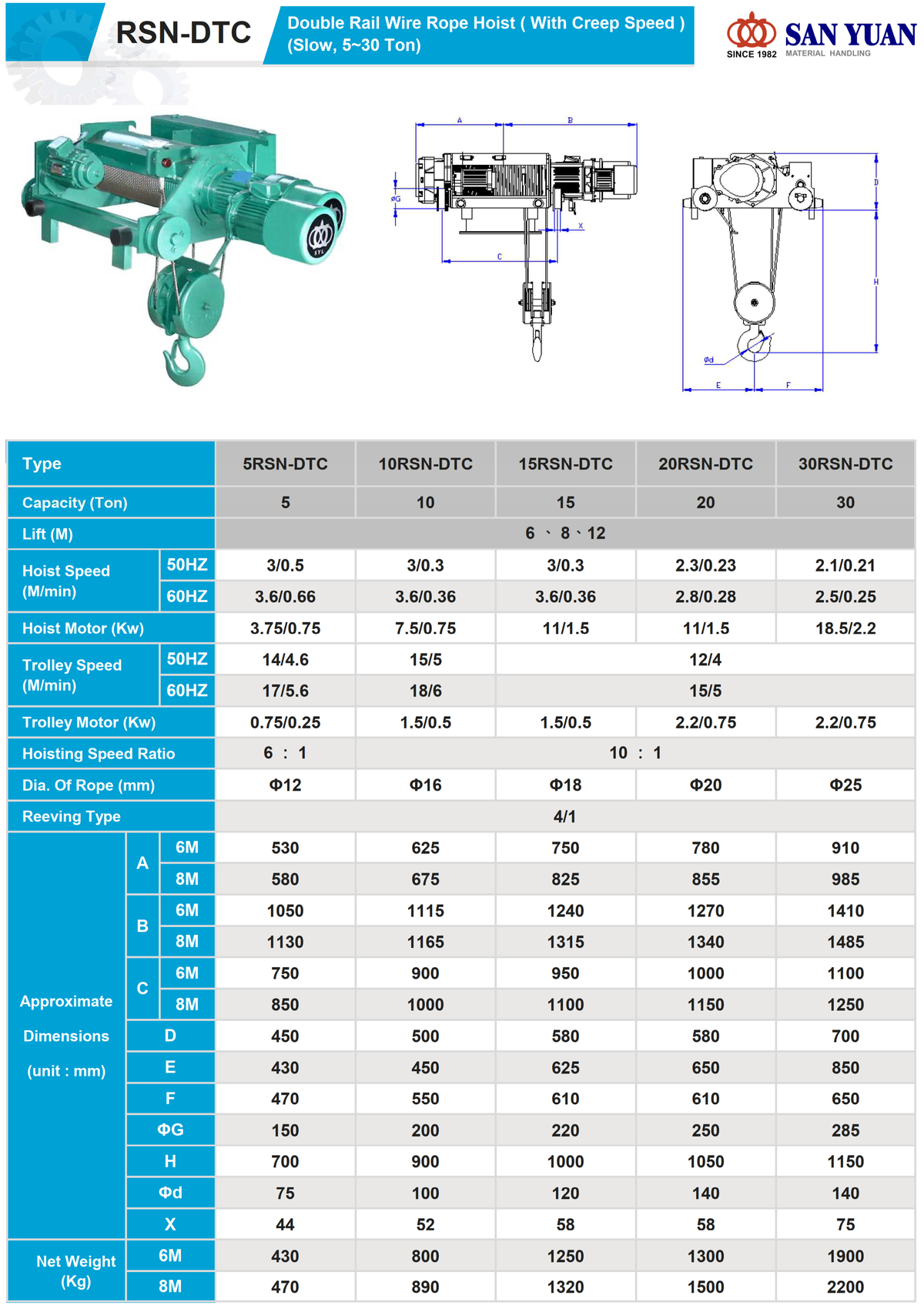

Double Rail Electric Wire Rope Hoist (Two Speed) R Type

( RFN-DTC & RSN-DTC )

Speed ratios 6:1 & 10:1

- The crane's classification standards are CNS Class C, DIN 2m, and ISO M5.

- Motor dustproof and waterproof rating: IP54

- Motor insulation class F

- The motor is rated for operation at S1 and features overheat protection with automatic stop and reset.

- Test load > 125%

- Braking torque > 150%

- Attached are test reports and factory certificates.

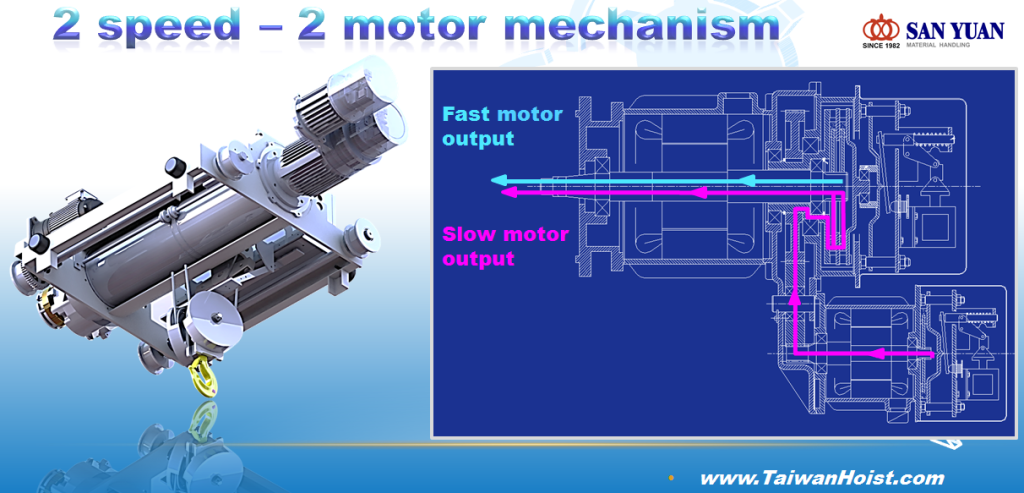

Dual-speed main crane model: Dual-motor RFN mechanism, variable frequency dual-speed electric crane.

Variable frequency dual-speed (optional): Equipped with a standard S1-class motor and featuring dynamic braking, the operating efficiency can reach 100%.

Dual-motor, dual-speed RFN mechanism design:

- The fast/slow speed motor and brake are independent, which is superior to the pole-changing motor.

- If one of the fast or slow motors fails, the other motor can still perform the lifting operation.

- With independent fast and slow motors, temperature rise is not concentrated on the same motor, improving efficiency and lifespan.

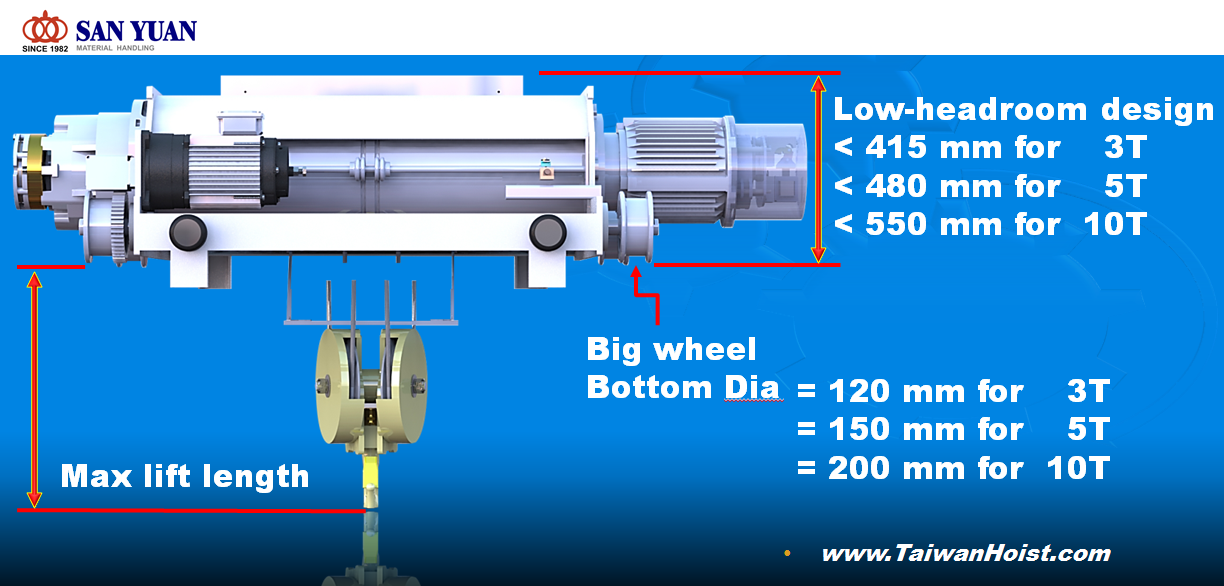

Appearance

- Low headroom design, takes up little space.

- The rigid shell design eliminates vibration and noise generated under load.

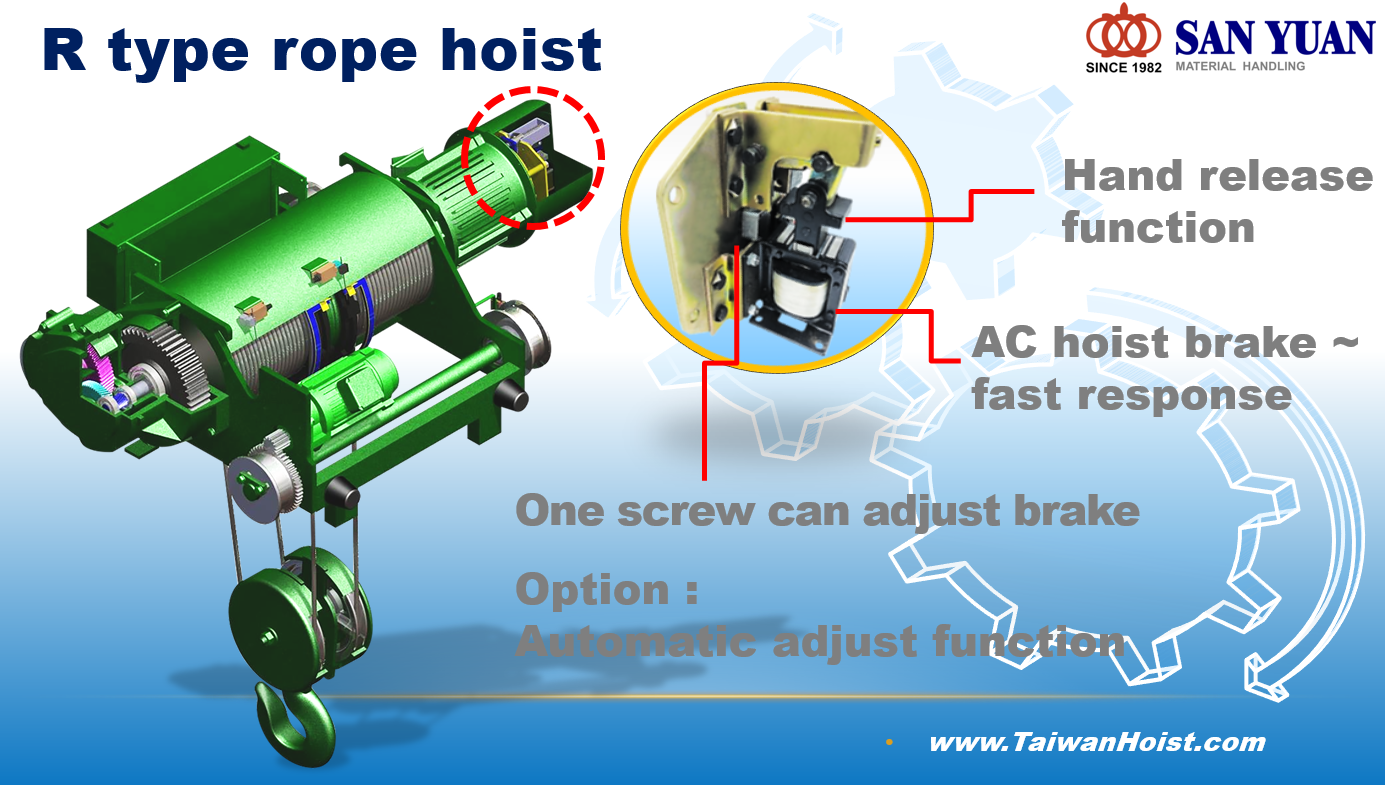

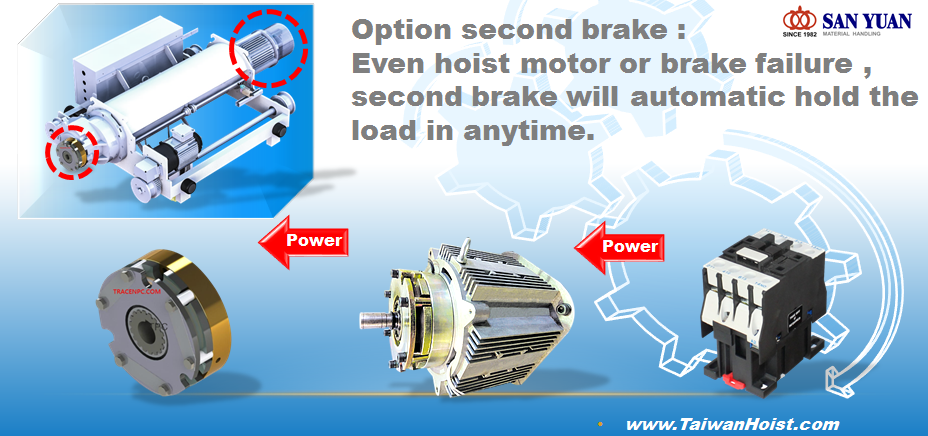

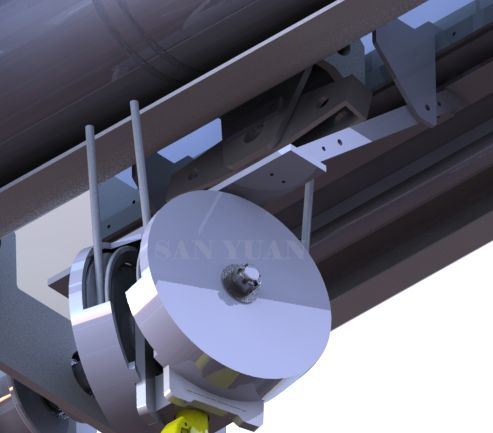

Brake

- The main crane brake uses an AC electromagnetic brake, which has a faster response speed than a DC brake.

- It has a manual release function.

- Both the main crane brake and the traverse brake are designed so that they can be adjusted using only a single bolt.

Optional – Electromagnetic auxiliary safety brake, which prevents the brake from opening when the motor is not powered, ensuring safety.

Roll design The 42-hook design ensures that the hook remains centered during lifting and lowering, guaranteeing safe positioning.

- The roll comes with strength calculations and material certificates.

Security features

- A suspended push-button switch with an emergency stop function.

- Automatic stop function at the upper limit position of the hook.

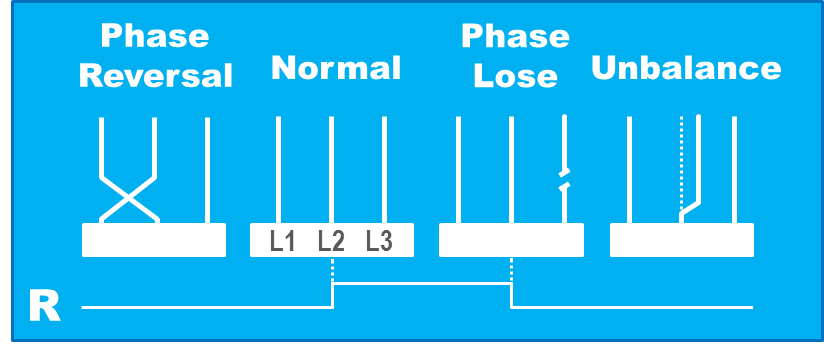

Power supply phase loss and reverse direction protection functions.

Optional – The guide cable can also have an automatic stop function at the lower limit position of the hook.

Optional – Overweight protection device; if digital, it can also be used as a weight display.

Gearbox Design

- The casing is made of cast iron to reduce noise and uses ground gears.

- Gearbox material = FCD45

Hook design

- Safety factor > 5.。

- Equipped with a thrust bearing, it can be manually rotated 360 degrees under full load.

- Attached are test reports and material certificates.

- Optional – VType of hook: This increases the length of steel cable that the drum can hold and optimizes the angle at which the steel cable is wound into the drum.

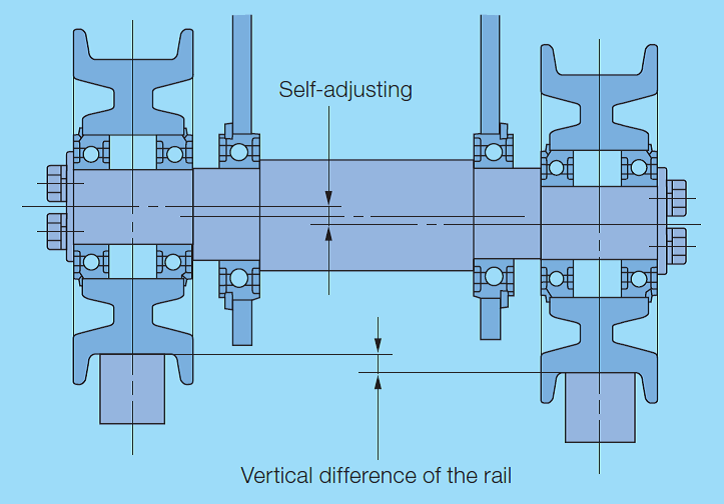

Double-rail trolley – self-aligning The design allows for eccentricity of the driven trolley axle, overcoming track laying errors.

Control method: Suspension-type push-button switch

Power requirements: 3-phase 220/380/415/440/460V 50/60HZ

Optional

- Gear-type upper and lower limit devicesIt can prevent reverse winding or over-winding.

- Speed controlOptional features include: main hoist with dual-speed control for horizontal and vertical travel, stepless speed change, soft start and stop, etc.

- Radio Remote Controller: Can perform remote control.

- Rope GuideMade of spheroidal cast iron, it is wear-resistant, tensile-resistant, and temperature-resistant.

- Overload protection device for steel cablesOverload alarm and stop device.

- Forced Cooling FanA forced air diffuser is installed on the brake side of the motor, which is suitable for high-temperature environments or frequent lifting of cranes, and can effectively extend the life of the motor and brake.